- Home

- › Products

- › Cryogenic

- › Safety Valves

CRYOGENIC

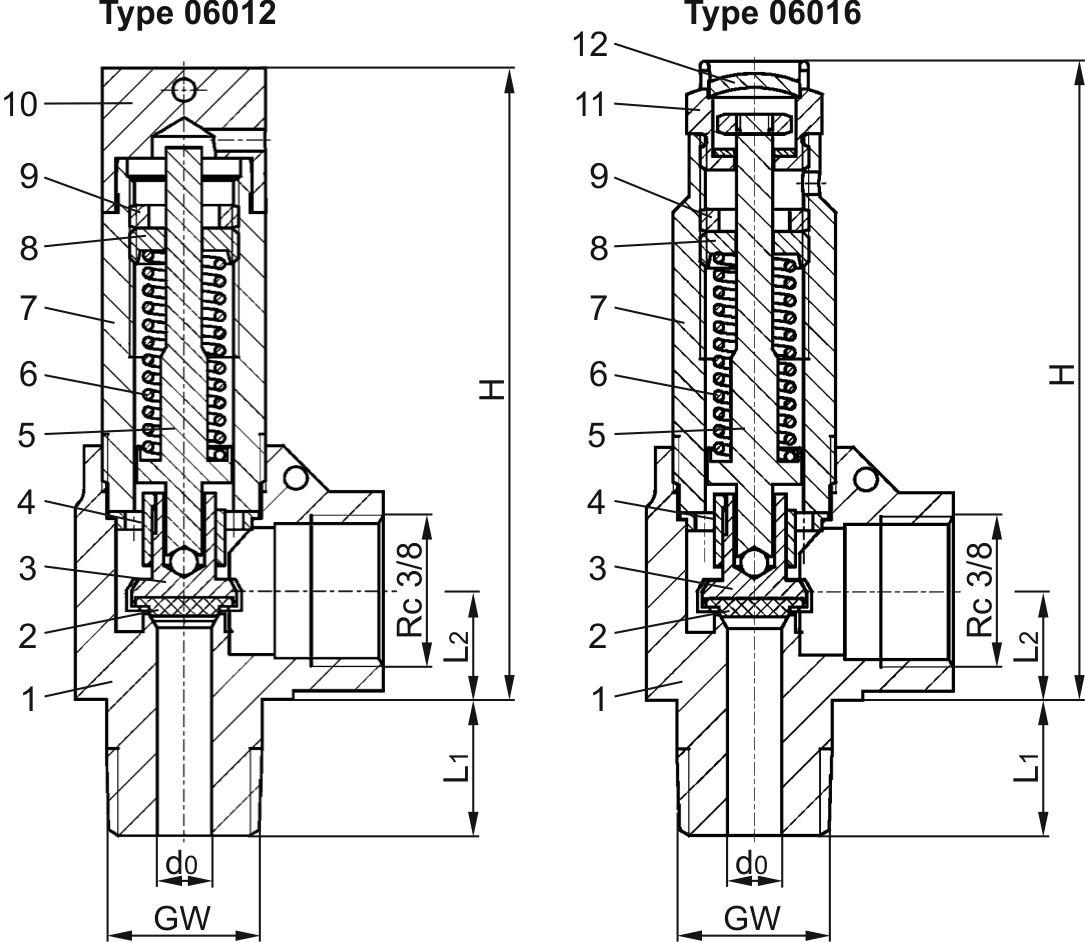

Type 06012, Type 06016

|

Cryogenic Safety Valves, angle type, stainless steel, PN63, type tested TÜV-SV.1048. S/G Standard safety valve, with carbon filled PTFE valve seal, open bonnet Outlet: female thread Rc 3/8 acc. to ISO 7/1, "cleaned and degreased for oxygen service" Type 06012: drainage hole in the locking screw Type 06016: drainage hole in the bonnet Part No. 06012.X.0000: Part No. 06016.X.0000 (with lifting device) Inlet: male thread type R (BSPT) acc. to ISO 7/1 Part No. 06012.X.2000 Part No. 06016.X.2000 (with lifting device) Inlet: male thread type G (BSPP) acc. to ISO 228/1 Part No. 06012.X.5000 Part No. 06016.X.5000 (with lifting device) Inlet: male thread NPT acc. to ANSI B 1.20.1 Available options - on request only: - with installed elbow at the outlet Applications: Provided as safety device for protection against thermal expansion in pipeworks and parts of facilities. Approved for air gases, vapours and cryogenic liquefied gases incl. LNG. Working temperature: -196°C / -321°F (77K) up to +150°C / +302°F (423K), suitable for horizontal installation |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Technical data | Type 06012 | Type 06016 | |||||

| Nominal size | GW | 1/4 | 3/8 | 1/2 | 1/4 | 3/8 | 1/2 |

| Orifice | d0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| Dimension code | .X. | 0200 | 0300 | 0400 | 0200 | 0300 | 0400 |

| Set pressure range | bar | 1.0-55.0 | 1.0-55.0 | 1.0-55.0 | 1.0-55.0 | 1.0-55.0 | 1.0-55.0 |

| Height | H | 70 | 70 | 70 | 72 | 72 | 72 |

| Length | L1 | 13 | 15 | 17 | 13 | 15 | 17 |

| Length | L2 | 13 | 13 | 13 | 13 | 13 | 13 |

| Weight | ca. kg | 0.185 | 0.20 | 0.22 | 0.18 | 0.195 | 0.21 |

| Coeff. of discharge from 3.0 bar | αw | 0.42 | 0.42 | 0.42 | 0.42 | 0.42 | 0.42 |

| Dimensions in mm. |

|

Discharge capacities Medium: Air in m³/h at 0°C and 1013.25 mbar Air in SCFM at 60°F (15.6°C) and 14.7 psia (1013.25 mbar) The capacity indicated below is for a fully opened valve. d0 - orifice A0 - flow area |

|

Calculation of discharge capacity acc. to AD2000-Merkblatt A2 / DIN EN ISO 4126-1 resp. ASME Code Sec. VIII.

|

| Set pressure in bar (ü) | GW | 1/4, 3/8 & 1/2 |

| d0 (mm) | 6.0 | |

| A0 (mm²) | 28.3 | |

| Medium | Air in m³/h | |

| 1.0 | 15 | |

| 2.0 | 26 | |

| 3.0 | 35 | |

| 4.0 | 44 | |

| 5.0 | 53 | |

| 6.0 | 62 | |

| 7.0 | 71 | |

| 8.0 | 80 | |

| 9.0 | 89 | |

| 10.0 | 98 | |

| 12.0 | 116 | |

| 14.0 | 134 | |

| 16.0 | 152 | |

| 18.0 | 170 | |

| 20.0 | 190 | |

| 22.0 | 208 | |

| 24.0 | 226 | |

| 26.0 | 244 | |

| 28.0 | 262 | |

| 30.0 | 283 | |

| 32.0 | 301 | |

| 34.0 | 320 | |

| 36.0 | 338 | |

| 38.0 | 356 | |

| 40.0 | 378 | |

| 42.0 | 396 | |

| 44.0 | 415 | |

| 46.0 | 433 | |

| 48.0 | 452 | |

| 50.0 | 474 | |

| 52.0 | 493 | |

| 54.0 | 511 | |

| 55.0 | 521 |

| Set pressure in psig | GW | 1/4, 3/8 & 1/2 |

| d0 (inch) | 0.236 | |

| A0 (in²) | 0.044 | |

| Medium | Air in SCFM | |

| 72 | 32 | |

| 80 | 35 | |

| 90 | 38 | |

| 100 | 42 | |

| 110 | 46 | |

| 120 | 49 | |

| 130 | 53 | |

| 140 | 57 | |

| 150 | 61 | |

| 160 | 64 | |

| 170 | 68 | |

| 180 | 72 | |

| 190 | 75 | |

| 200 | 79 | |

| 225 | 88 | |

| 250 | 98 | |

| 275 | 107 | |

| 300 | 116 | |

| 325 | 125 | |

| 350 | 135 | |

| 375 | 144 | |

| 400 | 153 | |

| 425 | 163 | |

| 450 | 172 | |

| 475 | 181 | |

| 500 | 190 | |

| 525 | 200 | |

| 550 | 209 | |

| 575 | 218 | |

| 600 | 227 | |

| 625 | 237 | |

| 650 | 246 | |

| 675 | 255 | |

| 700 | 264 | |

| 725 | 274 | |

| 750 | 283 | |

| 775 | 292 | |

| 798 | 301 |

- CE approval

- TPED approval

- ABS approval

- BV approval

- LR approval

- RINA approval

- RMRS approval

- ClassNK approval

- Vd TÜV type test approval

- UKCA approval

- Type Test Specific Equipments CHINA

- EU type-examination module B

- Installation/operating instruction

- Conformity declaration (CE)

- Conformity declaration (Pi)