- Home

- › Products

- › Cryogenic

- › Overflow Valves

CRYOGENIC

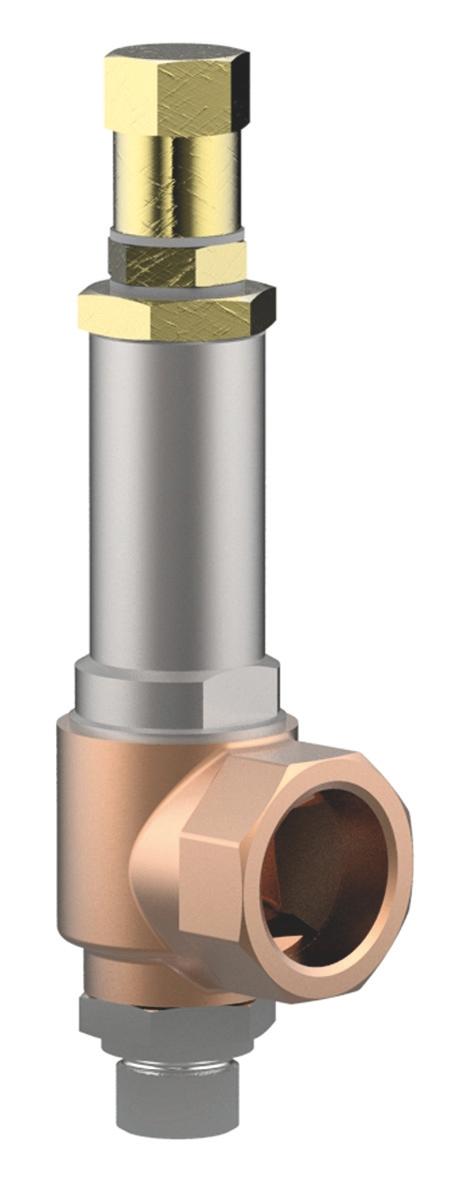

Type 06386

|

Cryogenic Overflow Valves, angle type, bronze, PN40, not type tested with adjusting device, metal to metal seated, closed bonnet Inlet: male thread type G (BSPP) acc. to ISO 228/1 Outlet: female thread type G (BSPP) acc. to ISO 228/1 "cleaned and degreased for oxygen service" Part No. 06386.X.9005 (0.5 up to 1.5 bar) Part No. 06386.X.9003 (1.0 up to 4.0 bar) Part No. 06386.X.9001 (3.0 up to 8.0 bar) Part No. 06386.X.9002 (7.0 up to 17.0 bar) Part No. 06386.X.9004 (16.0 up to 20.0 bar) Part No. 06386.X.9007 (21.0 up to 28.0 bar) Part No. 06386.X.9006 (28.0 up to 36.0 bar) Available options - on request only: - other spring ranges acc. to customer specification Applications: Provided as overflow valve for protection against excessive pressure in pipe systems and pressure vessels, which are not subject to approval. Working temperature: -196°C / -321°F (77K) up to +185°C / +365°F (458K) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

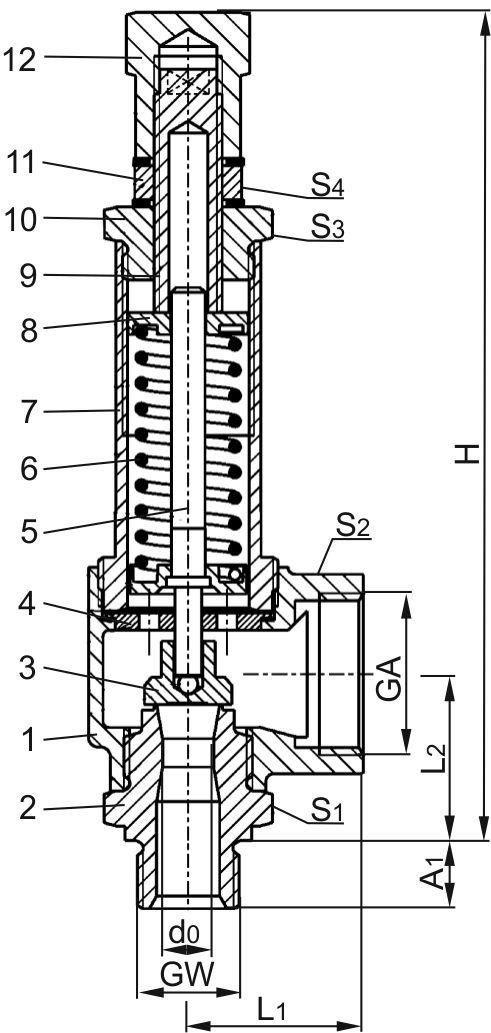

| Type 06386 | Technical data | ||

| Nominal size | GW | 1/2 | 3/4 |

| Orifice | d0 | 10.5 | 10.5 |

| Dimension code | .X. | 1004 | 1006 |

| Outlet | GA | 1 | 1 |

| Height | H | 171 | 171 |

| Length | L1 | 36 | 36 |

| Length | L2 | 34 | 34 |

| Length | A1 | 14 | 16 |

| Wrench size across flats | S1 | 30 | 32 |

| Wrench size across flats | S2 | 41 | 41 |

| Wrench size across flats | S3 | 30 | 30 |

| Wrench size across flats | S4 | 22 | 22 |

| Weight | ca. kg | 0.78 | 0.81 |

| Dimensions in mm. |

|

Discharge capacities Calculation of flow rate acc. to AD2000-Merkblatt A2 / DIN EN ISO 4126-1 Medium: Air in m³/h at 0°C and 1013.25 mbar The capacity indicated below is for 10% pressure increase. d0 - orifice A0 - flow area |

| Set pressure in bar (ü) | GW | 1/2 & 3/4 | ||||||

| d0 (mm) | 10.5 | |||||||

| A0 (mm²) | 86.6 | |||||||

| Medium | Air | |||||||

| Pressure range in bar | 0.5 - 1.5 | 1.0 - 4.0 | 3.0 - 8.0 | 7.0 - 17.0 | 16.0 - 20.0 | 21.0 - 28.0 | 28.0 - 36.0 | |

| 0.5 | 8 | - | - | - | - | - | - | |

| 1.0 | 11 | 6 | - | - | - | - | - | |

| 1.5 | 14 | 9 | - | - | - | - | - | |

| 2.0 | - | 12 | - | - | - | - | - | |

| 3.0 | - | 21 | 10 | - | - | - | - | |

| 4.0 | - | 32 | 25 | - | - | - | - | |

| 5.0 | - | - | 48 | - | - | - | - | |

| 6.0 | - | - | 76 | - | - | - | - | |

| 7.0 | - | - | 107 | 82 | - | - | - | |

| 8.0 | - | - | 144 | 104 | - | - | - | |

| 9.0 | - | - | - | 128 | - | - | - | |

| 10.0 | - | - | - | 155 | - | - | - | |

| 11.0 | - | - | - | 177 | - | - | - | |

| 12.0 | - | - | - | 217 | - | - | - | |

| 13.0 | - | - | - | 248 | - | - | - | |

| 14.0 | - | - | - | 280 | - | - | - | |

| 15.0 | - | - | - | 319 | - | - | - | |

| 16.0 | - | - | - | 361 | 186 | - | - | |

| 17.0 | - | - | - | 409 | 220 | - | - | |

| 18.0 | - | - | - | - | 263 | - | - | |

| 19.0 | - | - | - | - | 304 | - | - | |

| 20,0 | - | - | - | - | 339 | - | - | |

| 21.0 | - | - | - | - | - | 227 | - | |

| 22.0 | - | - | - | - | - | 244 | - | |

| 24.0 | - | - | - | - | - | 278 | - | |

| 25.0 | - | - | - | - | - | 296 | - | |

| 26.0 | - | - | - | - | - | 314 | - | |

| 28.0 | - | - | - | - | - | 353 | 431 | |

| 30.0 | - | - | - | - | - | - | 461 | |

| 32.0 | - | - | - | - | - | - | 491 | |

| 34.0 | - | - | - | - | - | - | 521 | |

| 35.0 | - | - | - | - | - | - | 536 | |

| 36.0 | - | - | - | - | - | - | 583 | |

| GW | 1/2 & 3/4 |

| Part No. spring | Pressure range of springs in bar |

| 55345.0114.1767 | 0.5 -1.5 |

| 55345.0263.0767 | 1.0 - 4.0 |

| 55345.0118.1767 | 3.0 - 8.0 |

| 55345.0119.1767 | 7.0 - 17.0 |

| 55345.0120.1767 | 16.0 - 20.0 |

| 55345.0233.0767 | 21.0 - 28.0 |

| 55345.0237.0767 | 28.0 - 36.0 |